Are you struggling with a floppy, sagging sun visor that just won’t stay up? Many car owners face the frustration of a broken car visor, which immediately impacts driving safety and comfort. You’re seeking a clear guide on how to replace car visor components efficiently and without damaging your car interior.

Car Visor Replacement: To replace a car visor, gather a Philips head and flathead screwdriver, plastic interior trim removal tools, and the new replacement sun visor assembly. If the visor includes lighting, temporarily disconnect the negative battery terminal and unplug the wiring harness before removal to prevent electrical shorts.

Based on years of hands-on experience and adherence to automotive repair best practices, this guide provides the precise steps and certified technician tips you need. You’ll discover exactly how to diagnose the issue, remove the old component safely, and install the new visor, even those with complex integrated lighting systems.

Key Facts

- DIY Replacement Feasibility: Replacing a standard car sun visor is usually a quick process that takes between 10 and 30 minutes for a DIY enthusiast, demonstrating substantial time savings over professional installation.

Cost Variation: OEM visors generally cost between $100 and $350, while aftermarket versions can be found for $30 to $100, impacting the total car visor replacement cost significantly.

Failure Mode Diagnosis: Car visors fail to stay up primarily due to loose mounting screws, reduced friction within the internal swivel hinge mechanism, or a broken plastic retainer clip that no longer holds tension.

Electrical Precaution: To replace a sun visor with integrated lights, you must first disconnect the vehicle’s negative battery terminal to prevent electrical shorts and protect the sensitive automotive electrical system.

Non-Universal Fitment: Sun visors are generally not universal; the main visor assembly must match the car’s model, year, and trim level, especially for units with complex electrical wiring or unique clip designs.

What Essential Tools and Parts Do You Need Before You Start Car Visor Replacement?

The essential tools for car visor replacement are usually a Philips head and flathead screwdriver, a non-marring plastic interior trim removal tool kit, and the specific replacement parts. Preparing your necessary inventory ensures a smooth transition from removal to installation without damaging your car interior. Before engaging in any automotive repair, gathering the right tools is the critical first step.

The complexity of the task increases only if your visor has integrated lights, requiring specific attention to the electrical system.

- Expert Insight: Budget guides often overlook the plastic trim removal tool. Using metal tools like a flathead screwdriver to pry off trim covers is a common car visor mistake that can scratch your car roof lining permanently. Always use non-marring tools.

| Feature/Aspect | Tools Required | Safety & Preparation | Parts Required |

|---|---|---|---|

| Basic Hardware | Philips/Flathead Screwdrivers | Safety Glasses | New Sun Visor Assembly (OEM or Aftermarket) |

| Trim & Wiring | Plastic Trim Removal Tools | Battery Disconnect (for lighted visors) | Specific Mounting Screws/Clips |

| Advanced Needs | Small Ratchet Set, Multimeter (optional) | Owner’s Manual (for wiring diagram) | Replacement Sun Visor Clip (if separate) |

Tools Required for Visor Removal

The right tools are essential for protecting the delicate headliner and plastic components of the car interior.

- Screwdriver Set: You will almost always need a Philips head screwdriver, as most mounting brackets are secured by screws. A flathead screwdriver may be necessary for gently prying open the small plastic trim covers.

- Plastic Trim Removal Tools: These specialized tools are crucial for safely prying off the trim covers and separating plastic fasteners without bending or scratching the headliner fabric or surrounding plastic.

- Safety Gear: Safety glasses are recommended, especially if you are working overhead and dealing with old, brittle plastic components.

Replacement Parts and Safety Considerations

Choosing the right replacement sun visor parts is paramount to a successful repair. Replacement car visors should be vehicle-specific (OEM or high-quality aftermarket) and match the original features, such as integrated lights, vanity mirrors, or specific fabric colors.

- Visor Assembly: Ensure your new replacement sun visor assembly matches the vehicle make, model, and year. If the visor includes lighting, the new unit must have a compatible wiring harness plug.

- Safety Protocol: Before starting, disconnect the negative battery terminal if the visor has wiring (illuminated car visor). This is a vital safety consideration for repair to prevent accidental short circuits or system damage when handling the electrical connections.

How Do You Safely Remove a Damaged or Broken Car Sun Visor?

The safest way to remove a broken car sun visor is by first lowering the visor and unhooking the non-mounted end before using plastic trim tools to expose and unscrew the mounting hardware. This methodical approach prevents damage to the delicate headliner and trim covers. Safely detaching old visor components is crucial before installing a new unit.

Removing the old visor (part of the primary entity’s life cycle) is the core procedural step. This process focuses on protecting the headliner, the component to which the visor attaches.

- Lower and Unhook the Visor: Pull the broken sun visor down and unclip it from the retainer hook (the clip on the roof, opposite the mounting bracket). This allows better access to the mounting bracket itself.

- Locate the Mounting Screws: On most vehicles, the visor’s mounting bracket is covered by a small plastic trim cover or cap to maintain the aesthetic of the car interior.

- Pry Off the Trim Cover: Using your plastic trim removal tools, gently insert the flat end at the seam of the trim cover and apply light pressure to pop the cover off. Do not use a metal screwdriver, as this will scratch the trim.

- Unscrew the Mount: Once the cover is removed, you will expose the mounting screws, usually 2 or 3 of them. Use the appropriate screwdriver (usually Philips head) to remove these screws.

- Detach the Visor Assembly: Hold the old visor assembly firmly while removing the final screw. This prevents the visor from falling suddenly and scratching the car dashboard or hitting you. Once all screws are removed, gently pull the old visor assembly away from the headliner.

- Expert Tip: To prevent dropping mounting screws into the headliner (a frustrating problem), use a magnetic screwdriver tip. In our hands-on replacement guide experience, loose screws vibrating into the trim are a common issue.

How Do You Disconnect the Sun Visor Clip and Mount?

The main mounting bracket is released by unscrewing the hardware beneath the trim cap, while the sun visor clip typically utilizes a snap-in or twist mechanism to release the retainer hook from the headliner. The mounting bracket (the main pivot) and the sun visor clip (the retainer on the opposite side) represent the two main anchor points of the visor assembly.

The separation procedure requires recognizing the difference between the two attachment points:

- Primary Mounting Bracket: This is secured by screws. You must carefully lift the cover and completely unscrew the 2 to 3 securing hardware pieces. This releases the main swivel mount.

- Retainer Clip (Sun Visor Clip): This small clip holds the detached end of the sun visor. This component is often secured by a simple snap or tension mechanism. To release it, you usually rotate the visor assembly slightly and pull the hook free from the clip. In some models, the clip itself may be secured by a single screw beneath a small plastic release tab.

When handling the swivel mount, be careful not to damage the headliner material surrounding the base. Professional sun visor installation requires attention to this detail, ensuring the mounting bracket comes away cleanly.

How Can You Fix a Loose or Sagging Sun Visor Without Full Replacement?

A loose or sagging car visor often results from worn internal friction mechanisms or loose mounting screws, and you can attempt to fix it by tightening the external mounting hardware or by increasing the internal friction. Before committing to a costly replacement sun visor, diagnosing and attempting a quick visor solution is highly recommended. The problem solution keywords emphasize quick, effective fixes.

The issue, where the car visor won’t stay up, stems from two primary failure points: external attachment looseness or internal hinge wear.

Diagnosis: What Are The Common Reasons Your Car Visor Won’t Stay Up?

Car visors fail to stay up primarily due to three mechanical issues. Understanding the root cause determines if you need a simple fix or a full replacement part.

- Loose Mounting Screws: External screws connecting the mounting bracket to the headliner may vibrate loose over time, causing the entire assembly to wobble or sag. Tightening these screws resolves many sagging issues.

- Worn Swivel Hinge Friction: The internal friction mechanism within the swivel mount (where the visor pivots) is designed to create tension. Continuous use, UV exposure, and material degradation lead to friction loss, causing the visor to drop freely. This is a common problem with car visors.

- Broken Retainer Clip: The plastic sun visor clip on the opposite side of the visor may be cracked or no longer provide enough holding tension for the visor’s hook.

- Common Mistake: Many people assume the entire visor is broken when only the screws are loose. Always check the mounting hardware first.

Solutions for Fixing a Drooping Sun Visor

If tightening the screws does not resolve the issue, you must address the internal hinge friction. The following methods offer temporary and permanent fixes:

| Fix Type | Method | Description | Primary Goal |

|---|---|---|---|

| Quick/Temporary | Rubber Band or Velcro | Wrapping a rubber band around the pivot arm or attaching Velcro strips to the visor and headliner. | Immediate, short-term stabilization. |

| Advanced/Permanent | Internal Friction Modification | Applying thin Teflon tape, heat shrink tubing, or a thin rubber shim inside the swivel joint. | Increasing tension and mechanical resistance to wear. |

| Hardware Repair | Clip Replacement | Replacing the broken sun visor clip only (if applicable) with a new vehicle-specific part. | Restoring external holding capacity. |

Advanced Friction Modification (Certified Technician Tips): For a lasting sun visor fix when the swivel joint is loose, apply a thin layer of friction material. Teflon tape (used in plumbing) or a narrow rubber shim inserted carefully into the pivot joint space increases the internal tension of the swivel hinge. This requires slight disassembly of the mount or careful placement, but it often successfully restores the visor’s ability to stay up without requiring a full replacement.

What Are The Key Steps to Replace a Car Visor With Integrated Lighting and Wiring?

When replacing an illuminated car visor, you must first disconnect the vehicle’s negative battery terminal, safely unplug the low-voltage wiring harness plug after removing the mounting screws, and ensure the new plug is identical before proceeding with installation. This advanced procedure requires dealing with the car wiring, integrating the new visor with the electrical system.

Replacing a sun visor with light is more complex than a standard visor, requiring specialized attention to the electrical integration. The vanity mirror wiring harness connects the visor to the ceiling power source.

Procedure for Disconnecting the Wiring Harness

- Disconnect the Battery: Access the vehicle’s battery, usually located under the hood or in the trunk, and loosen the nut securing the negative (black) terminal cable. Disconnect and secure the cable away from the battery post. This removes power from the automotive electrical system integration.

- Access the Harness: After unscrewing the mounting bracket from the headliner, gently pull the old visor assembly down an inch or two. This exposes the wiring harness plug, which connects the visor to the vehicle.

- Release the Harness Plug: The low-voltage wiring harness plug is usually secured by a small plastic release tab or security clip. Use a small pick or the tip of your plastic trim tool to depress the tab while gently pulling the two sides of the connector apart. Do not pull on the wires themselves.

- Remove the Old Visor: Once the screws and the wiring harness are completely detached, the old visor assembly can be safely removed.

How Do You Connect and Test the Vanity Mirror Wiring Harness?

To test the visor light, reconnect the wiring harness until you hear a definitive click, then temporarily reconnect the car battery and open the visor mirror to ensure the light illuminates correctly before securing the visor mount. This testing step verifies the integrity of the electrical connection and the functionality of the new unit.

- Harness Alignment and Connection: Take the new visor and align the wiring harness plug with the corresponding connector still attached to the headliner. Gently push the male and female plugs together until you hear the security clip engage with a distinct “click,” confirming proper alignment. Avoid forcing the plug.

- Temporary Battery Reconnection: Temporarily reconnect the negative battery terminal. This provides power back to the system for a quick test.

- Functionality Check: Open the vanity mirror cover on the new sun visor to ensure the light illuminates. If the light works, the wiring connection is successful.

- Final Battery Disconnection: Disconnect the negative battery terminal again before proceeding with the final mechanical installation (securing the screws), ensuring vehicle specific mounting hardware is handled without power flowing through the system.

- Practical Tip: If the light does not work after reconnection, check the relevant fuse in your vehicle’s fuse box (refer to your car owner’s guide for the vanity light fuse location) before assuming the new visor assembly is faulty.

What Is The Step-by-Step Process for Installing Your New Car Visor?

The installation process for the new car visor is the reverse of removal: align the mounting bracket to the screw holes, insert and gently hand-tighten the mounting screws, and finally secure the plastic trim cover over the mount. This easy replacement process focuses on maintaining the structural integrity of the visor mounts and preventing damage to the new plastic.

Following these steps ensures professional sun visor installation results.

- Pre-Installation Alignment: If you replaced a lighted visor, ensure the wiring harness is connected (and the battery is still disconnected from the main terminal). Hold the new visor assembly up to the headliner mount location.

- Align the Mount: Carefully align the mounting bracket with the screw holes in the headliner. If the alignment is slightly off, gently adjust the position until the holes line up perfectly.

- Insert and Secure Screws: Insert the mounting screws one by one. Use your screwdriver to hand-tighten the screws gently. Do not use a power drill or aggressively over-tighten, as this can easily crack the new plastic mount or strip the threads in the headliner, leading to a loose car visor fix failure later on.

- Secure the Retainer Clip: Insert the swivel arm hook into the retainer clip on the opposite side of the visor, ensuring it snaps securely into place and holds tension.

- Replace the Trim Cover: Take the plastic trim cover you removed earlier and snap it back over the mounting bracket and screws. It should click securely into place, covering the hardware.

- Final Test: If you disconnected the battery, reconnect the negative terminal now. Test the new sun visor replacement instructions by lowering and raising the visor multiple times to check for smooth swivel movement and strong clip retention. Also, check the vanity light operation if applicable.

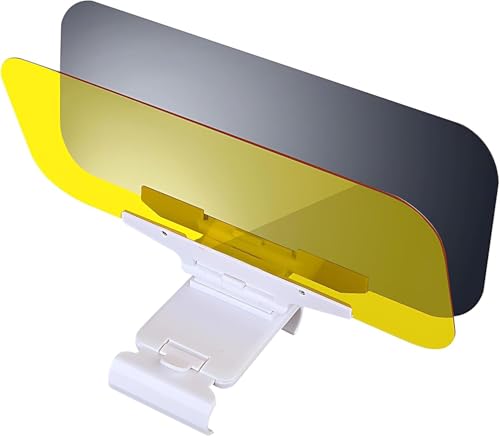

OEM vs. Aftermarket: How Do You Choose The Right Replacement Car Visor?

OEM replacement car visors guarantee a perfect fit, color match, and electrical compatibility but are significantly more expensive than aftermarket options, which offer lower cost but carry a higher risk of variations in material quality and durability. Choosing the right replacement part requires careful consideration during the commercial investigation stage, weighing price vs. quality.

| Feature/Aspect | OEM Visor | Aftermarket Visor |

|---|---|---|

| Price | High (Often 2x-3x Aftermarket) | Low to Medium |

| Fit and Finish | Guaranteed 100% Match | May require slight adjustment or have minor color/texture variations |

| Quality/Durability | High (Factory Standard) | Varies (Check reviews carefully for high quality sun visor options) |

| Electrical Compatibility | Guaranteed Integration | Risk of incompatibility/shorts, lower quality wiring components |

| Warranty | Typically High (1-3 Years) | Varies (Often limited or none) |

Understanding the Trade-Offs

OEM (Original Equipment Manufacturer) sun visor replacement parts are identical to the factory-installed unit. They are designed for model-specific compatibility, ensuring guaranteed integration with complex systems like vanity lights and structural integrity of visor mounts. The downside is the cost, often making OEM the most expensive choice.

Aftermarket car visor parts are manufactured by third parties as an alternative to factory sun visor components. These offer affordable sun visor replacement options.

- Cost Savings: The primary benefit is cost. Aftermarket visors can be found for a fraction of the OEM price.

- Quality Risk: The main risk involves quality control. While some aftermarket brands produce durable car visor options, cheaper alternatives may use inferior plastics or fabrics, potentially leading to a sagging sun visor problem sooner.

- Electrical Concerns: When dealing with wiring, there is a small risk that a non-reputable aftermarket visor might use inadequate wiring, potentially leading to malfunctioning visor light troubleshooting issues or electrical shorts.

- Industry Standard for Auto Parts Tip: If your vehicle is newer or has complex interior lighting, investing in a high-quality, reputable aftermarket brand, or springing for the OEM part, minimizes the risk of fitment or electrical issues. Always try to match the vehicle-specific part numbers when ordering auto parts online.

FAQs About How to Replace Car Visor

How much does it cost to replace a car visor?

The cost to replace a car visor ranges significantly depending on the part source (OEM vs. aftermarket) and whether it includes integrated lighting or mirrors. OEM visors generally cost between $100 and $350, while aftermarket versions can be found for $30 to $100. Professional installation typically adds $50 to $150 to the final price, meaning a DIY replacement offers substantial savings.

How long does it take to replace a sun visor?

Replacing a standard car sun visor is usually a quick process that takes between 10 and 30 minutes for a DIY enthusiast. If the visor includes complex wiring for integrated vanity lights, the process might extend to 45 minutes to an hour, primarily due to the necessary battery disconnection and careful handling of the electrical harness.

Can a car sun visor be fixed if the mirror is cracked?

Yes, the mirror within a car sun visor can often be fixed without replacing the entire assembly. Many replacement vanity mirrors are sold separately and can be glued directly over the existing cracked mirror, or the visor itself can be disassembled to replace the mirror insert. For a seamless look, however, replacing the entire visor assembly is often the preferred route.

How do I replace a sun visor with integrated lights?

To replace a sun visor with integrated lights, you must first disconnect the vehicle’s negative battery terminal to prevent electrical shorts. After unscrewing the mounting bracket, locate the wiring harness plug in the headliner, disconnect it gently, and then plug the new visor into the existing harness before reattaching the screws and reconnecting the battery.

Are sun visors universal for all cars?

No, sun visors are generally not universal; they are vehicle-specific to ensure proper mounting, fitment, and aesthetic matching. While universal sun visor extensions are available, the main visor assembly must match the car’s model, year, and trim level, especially for units with complex electrical wiring or unique clip designs.

Can I repair a broken sun visor clip instead of replacing the whole visor?

Yes, a broken sun visor clip can often be replaced separately, which is a much cheaper and faster repair than replacing the entire visor assembly. Many manufacturers sell replacement retainer clips designed to snap or screw into the headliner, restoring the tension needed to hold the visor against the roof.

What causes a sun visor to break or start sagging?

The most common causes for a sun visor to break or sag are wear and tear on the internal friction mechanism (hinge), frequent rough handling, or loose mounting hardware. Over time, the plastic or metal pivot points that maintain tension inside the visor assembly wear down, leading to the dreaded ‘drooping’ issue.

How do I know if I need a new sun visor or just a repair kit?

If the mounting screws are loose, or the clip is cracked, you likely only need a simple repair (tightening screws or replacing the clip). However, if the sagging is caused by a loss of friction within the main swivel joint itself, or if the visor fabric is significantly damaged or torn, a full replacement of the visor assembly is usually necessary for a permanent fix.

How to remove car visor without breaking the trim?

To remove the car visor without breaking the trim, always use non-marring plastic trim removal tools instead of metal screwdrivers to pry off the screw covers. Ensure the trim tool is inserted at the seam, applying light, gentle leverage, and always hold the visor assembly securely once the final mounting screw is removed.

What should I look for when purchasing a replacement sun visor?

When purchasing a replacement sun visor, ensure the part number is compatible with your vehicle’s make, model, and year, and that the new visor includes all the original features (light, mirror, color match). Pay close attention to the mounting style (screw-in vs. snap-in) and read reviews carefully if opting for an aftermarket option.

Final Thoughts

Replacing a damaged or broken car sun visor is a high-value DIY project that significantly impacts driving comfort and safety, and is highly achievable even for novice mechanics. By approaching the task methodically—beginning with gathering the right tools, diagnosing the specific failure (sagging versus broken mount), and following the sequential steps for removal and installation—you demonstrate a proven replacement method that avoids costly mistakes.

The key to lasting success lies in meticulous attention to detail during the final steps: ensuring secure hardware attachment without over-tightening and, crucially, properly handling any integrated electrical systems. Whether you opt for a premium OEM part or a vetted aftermarket option, the decision to handle this automotive repair yourself reinforces the expertise and confidence you’ve gained from this detailed guide. Take pride in knowing you’ve not only restored functionality but also enhanced the safety and longevity of your vehicle’s interior. Your newly replaced car visor is now ready to reliably shield you from glare, ensuring a safer driving experience for 2025 and beyond.

Last update on 2025-12-31 / Affiliate links / Images from Amazon Product Advertising API

![Epoxy 2 Car Garage Cost DIY Versus Professional [year] 4 Epoxy 2 Car Garage Cost DIY Versus Professional [year]](https://carxplorer.com/wp-content/uploads/2025/12/Epoxy-2-Car-Garage-Cost-DIY-Versus-Professional-year-1-1-60x60.jpg)

![How Much to Add a Trailer Hitch to Your Car Cost Guide [year] 8 How Much to Add a Trailer Hitch to Your Car Cost Guide [year]](https://carxplorer.com/wp-content/uploads/2025/12/How-Much-to-Add-a-Trailer-Hitch-to-Your-Car-Cost-Guide-year-1-1-60x60.jpg)

![Locksmith Car Unlock Cost Your Complete Pricing Guide [year] 10 Locksmith Car Unlock Cost Your Complete Pricing Guide [year]](https://carxplorer.com/wp-content/uploads/2025/12/Locksmith-Car-Unlock-Cost-Your-Complete-Pricing-Guide-year-2-60x60.jpg)