Ever wondered about the labels and acronyms associated with your car battery? Seeing “SDS” mentioned might leave you scratching your head, especially when dealing with potentially hazardous materials like those found in batteries. Many people find navigating safety documentation confusing, unsure what information is truly crucial for handling, transporting, or disposing of car batteries safely.

SDS on a car battery stands for Safety Data Sheet. It’s a mandatory document under OSHA regulations detailing the battery’s chemical hazards, safe handling procedures, emergency measures, and composition (like lead-acid or lithium-ion), ensuring workplace safety and compliance during transport.

Understanding this documentation isn’t just about compliance; it’s fundamental to protecting yourself, others, and the environment. This guide will demystify the meaning of SDS for car batteries, explaining why it’s essential, when it’s required by regulations like OSHA’s Hazard Communication Standard, how it differs from other safety documents, and where you can find one. Get ready to decode battery safety information like a pro.

Key Facts:

* Mandated Standard: The Occupational Safety and Health Administration’s (OSHA) Hazard Communication Standard (HCS – 29 CFR 1910.1200) requires Safety Data Sheets for hazardous chemicals in the workplace, including components in many car batteries.

* GHS Alignment: Modern SDS documents follow a standardized 16-section format mandated by the Globally Harmonized System of Classification and Labelling of Chemicals (GHS).

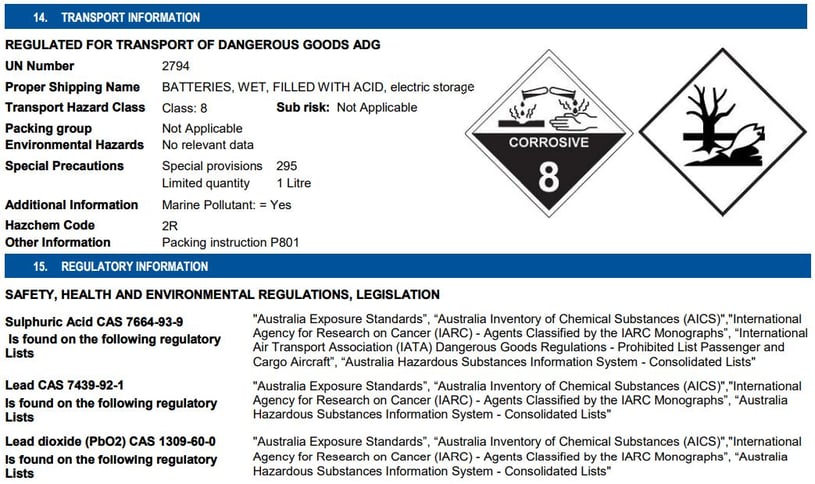

* Transport Regulation: Car batteries are often classified as hazardous materials for transport (e.g., UN2794, Class 8 Corrosive for wet lead-acid batteries), requiring an SDS for shipping compliance.

* Chemical Disclosure: An SDS must detail hazardous ingredients, such as lead compounds and sulfuric acid in lead-acid batteries or lithium compounds in lithium-ion batteries.

* Accessibility: Employers are required by OSHA to ensure SDSs for hazardous chemicals are readily accessible to employees during their work shifts.

What is a Safety Data Sheet (SDS) and Why Does it Matter for Car Batteries?

A Safety Data Sheet (SDS) is a standardized, comprehensive document providing critical information about the properties, potential hazards, safe handling, storage, transport, disposal, and emergency control measures for a chemical substance or mixture. Think of it as an essential safety manual for potentially hazardous products, including many types of car batteries.

Why is this so important for car batteries? Because whether they are traditional lead-acid types containing corrosive sulfuric acid and toxic lead, or newer lithium-ion chemistries with flammable electrolytes, car batteries contain materials that pose risks if mishandled. The SDS serves as the primary tool for communicating these hazards and the necessary precautions to ensure safety for workers, emergency responders, and anyone involved in their lifecycle. It bridges the information gap between the battery manufacturer and the end-user or handler.

Understanding the Purpose of an SDS

The core purpose of an SDS is hazard communication. It aims to ensure that anyone who handles, transports, stores, uses, or disposes of the substance has the necessary information to do so safely. Key objectives include:

- Identifying the substance and its manufacturer/supplier.

- Detailing the potential physical, health, and environmental hazards.

- Providing instructions for safe handling, storage, and transport.

- Outlining first-aid measures in case of accidental exposure.

- Specifying procedures for dealing with spills, fires, or accidental releases.

- Listing necessary personal protective equipment (PPE).

- Providing information on disposal considerations and regulatory status.

Essentially, the SDS empowers users with the knowledge needed to minimize risks associated with the battery’s chemical components.

Key Information Contained in a Car Battery SDS

While the specifics vary by battery type (lead-acid vs. lithium-ion vs. AGM), a car battery SDS, following the standardized 16-section GHS format, typically includes:

- Identification: Product name (e.g., “Lead Acid Battery, Wet, Filled With Acid”), manufacturer/supplier contact details, recommended use, and restrictions.

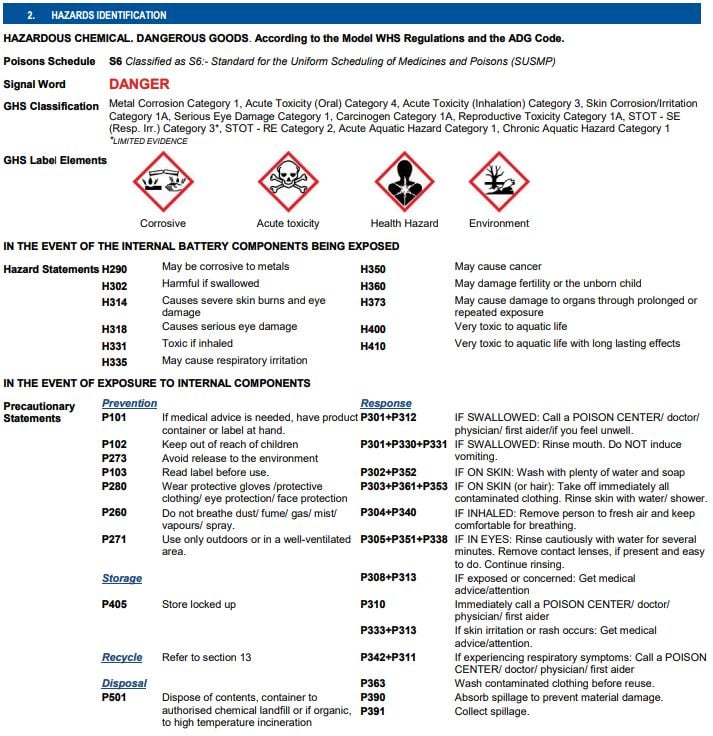

- Hazard(s) Identification: Classification of hazards (e.g., Corrosive, Health Hazard), signal words (“Danger” or “Warning”), hazard statements (e.g., “Causes severe skin burns and eye damage”), and precautionary statements.

- Composition/Information on Ingredients: Lists hazardous chemical components like Lead, Lead Compounds, Sulfuric Acid (for lead-acid), or Lithium compounds and electrolytes (for lithium-ion), including concentration ranges.

- First-Aid Measures: Instructions for immediate care following exposure (inhalation, skin/eye contact, ingestion).

- Fire-Fighting Measures: Suitable extinguishing agents, specific hazards arising from the chemical during a fire (e.g., emission of toxic fumes), and protective equipment for firefighters.

- Accidental Release Measures: Procedures for containment and cleanup of spills or leaks, personal precautions, and environmental precautions.

- Handling and Storage: Guidelines for safe handling practices and appropriate storage conditions (e.g., temperature limits, ventilation).

- Exposure Controls/Personal Protection: Occupational exposure limits (OELs), engineering controls (like ventilation), and recommended personal protective equipment (PPE) such as gloves, eye protection, and respiratory protection.

- Physical and Chemical Properties: Appearance (e.g., “Manufactured article”), odor, pH (of electrolyte), flammability limits, etc.

- Stability and Reactivity: Chemical stability, possibility of hazardous reactions, conditions to avoid (e.g., heat, sparks), and incompatible materials.

- Toxicological Information: Routes of exposure, symptoms, acute and chronic health effects (based on components like lead or acid).

- Ecological Information: Potential environmental impact (though often limited data for the battery article itself).

- Disposal Considerations: Guidance on safe disposal methods, emphasizing compliance with local, state, and federal regulations. Recycling is heavily promoted for batteries.

- Transport Information: UN number (e.g., UN2794 for wet lead-acid), proper shipping name, hazard class (e.g., Class 8 Corrosive), packing group, and any special precautions.

- Regulatory Information: Safety, health, and environmental regulations specific to the product (e.g., OSHA HCS compliance, TSCA status).

- Other Information: Date of preparation or last revision, and sometimes a disclaimer.

This structured information ensures that crucial safety data is consistently presented and easy to locate.

What Does SDS Mean on a Car Battery and When is it Required?

Specifically on a car battery context, SDS refers to the Safety Data Sheet document that outlines the potential hazards and safe handling procedures for that particular type of battery. It’s not usually printed directly on the battery itself, but it’s a critical piece of documentation associated with it, especially in commercial, industrial, or transportation settings.

The requirement for an SDS hinges on regulatory frameworks, primarily those related to workplace safety and the transportation of hazardous materials.

Workplace Safety and OSHA Requirements

The primary driver for SDS requirements in the United States is OSHA’s Hazard Communication Standard (HCS) (29 CFR 1910.1200). This standard mandates that chemical manufacturers and importers evaluate the hazards of the chemicals they produce or import and prepare labels and safety data sheets to convey the hazard information to downstream users.

- Employer Responsibility: Employers who have hazardous chemicals (including many types of batteries) in their workplaces must have an SDS for each one and ensure they are readily accessible to employees who may be exposed. This applies to auto repair shops, battery retailers, distribution centers, recycling facilities, and manufacturing plants.

- Employee Right-to-Know: The HCS ensures employees have the right to know about the hazards they might encounter in the workplace and how to protect themselves. The SDS is a key tool for fulfilling this requirement.

If your workplace involves handling, storing, charging, or installing car batteries (especially outside of a consumer context), OSHA requires that the relevant SDS be available.

Transportation Regulations for Car Batteries

Car batteries are frequently classified as hazardous materials (HazMat) or dangerous goods for transportation due to their corrosive, reactive, or potentially flammable components.

- DOT Classification: The U.S. Department of Transportation (DOT) classifies materials based on their hazards. For example:

- Wet, filled lead-acid batteries are typically Class 8 (Corrosive materials), UN Number UN2794.

- Non-spillable batteries (like AGM or Gel) might be Class 8, UN Number UN2800, but often qualify for exceptions if they meet specific criteria.

- Lithium-ion batteries are generally Class 9 (Miscellaneous hazardous materials), with various UN numbers (e.g., UN3480, UN3481) depending on whether they are shipped alone or contained in equipment.

- SDS for Shipping: When shipping batteries classified as hazardous materials, transport regulations (DOT in the US, IATA for air, IMDG for sea) often require the shipper to provide the carrier with appropriate documentation, which typically includes or is based on information found in the SDS. The SDS confirms the hazard classification, necessary labeling, packaging requirements, and emergency response information. Shipping companies will almost always require an SDS before accepting potentially hazardous battery shipments.

Consumer Product Exceptions

It’s important to note that an SDS is generally not required for a standard car battery already installed in a vehicle for consumer use, nor typically provided to the consumer upon purchase of a replacement battery for immediate installation. Consumer products often fall under different labeling regulations (like the Consumer Product Safety Commission – CPSC).

However, the moment that same battery is handled in bulk, shipped separately, stored in a workplace, or managed for disposal/recycling, the OSHA and DOT regulations kick in, and an SDS becomes necessary for compliance and safety.

How Does an SDS Differ From Other Battery Safety Documents?

It’s easy to get confused with the various acronyms and documents surrounding battery safety. While an SDS is comprehensive, other specific documents serve different, though sometimes overlapping, purposes. An SDS provides broad hazard communication, while other documents like MSDS (an older format), Lithium Battery Test Summaries (verifying transport safety tests), and Emergency Response Guides (for first responders) serve more specialized roles.

Here’s a breakdown of how an SDS compares to other common battery-related safety documents:

SDS vs. Material Safety Data Sheet (MSDS)

- SDS (Safety Data Sheet): This is the current, globally standardized format for hazard communication, aligned with the GHS (Globally Harmonized System). It features a mandatory 16-section structure, standardized language, and specific pictogram requirements. Its primary goal is consistent and clear communication of hazards worldwide.

- MSDS (Material Safety Data Sheet): This was the older format used in the U.S. (and other regions) before the adoption of GHS. MSDSs varied significantly in format, section order, and level of detail, making them less consistent and sometimes harder to interpret than the standardized SDS. Essentially, SDS replaced MSDS. If you encounter an MSDS for a battery, it’s likely outdated, and an updated SDS should be sought.

Think of it like standardizing electrical plugs globally – the SDS provides a consistent format everyone recognizes, while MSDS was like having different plug types in every country.

Lithium Battery Test Summary (TS) Explained

- SDS: Provides overall hazard information for lithium batteries, including chemical risks, handling, and emergency procedures.

- Test Summary (TS): This document is specifically required for the transportation of lithium cells and batteries. It confirms that the battery has passed the rigorous safety tests outlined in the UN Manual of Tests and Criteria, Part III, subsection 38.3. These tests simulate transport conditions like altitude, thermal changes, vibration, shock, short circuits, and overcharging. The TS doesn’t detail chemical hazards like an SDS; instead, it serves as proof of compliance with UN 38.3 transport safety testing. Manufacturers and subsequent distributors must make this TS available. It’s a prerequisite for legal transportation, distinct from the broader hazard info in an SDS.

Emergency Response Guides for EV Batteries

- SDS: Contains basic first-aid and fire-fighting information applicable to the battery’s chemical components.

- Emergency Response Guide (ERG) / Emergency Response Datasheet: These are highly specialized documents, particularly crucial for Electric Vehicle (EV) high-voltage battery packs. They provide detailed, vehicle-specific instructions for first responders (firefighters, EMTs) arriving at an accident scene involving an EV. ERGs cover critical procedures like locating and disabling the high-voltage system, specific fire-fighting techniques for lithium-ion battery fires (which can be complex and prone to reignition), and extrication considerations. While an SDS covers general chemical hazards, an ERG provides actionable, tactical guidance for emergency personnel dealing with the unique challenges of large, high-voltage automotive battery systems.

Key Takeaway: While all these documents relate to battery safety, they serve different audiences and regulatory requirements. SDS is for general hazard communication (workplace/transport), TS is proof of lithium battery transport testing, and ERGs are specialized guides for first responders, especially for EVs.

Where Can You Typically Find a Car Battery SDS?

Finding the correct Safety Data Sheet for a specific car battery is usually straightforward if you know where to look. The primary sources are the battery manufacturer’s or supplier’s official websites, often found in sections dedicated to product support, resources, or safety information.

Here’s a breakdown of common places to obtain a car battery SDS:

Checking Manufacturer Websites

This is often the most reliable source for an up-to-date SDS. Major battery manufacturers understand their regulatory obligations and typically make these documents publicly available online.

- Navigate to the Manufacturer’s Website: Go to the official website of the battery brand (e.g., Interstate Batteries, East Penn (Deka), Clarios (Varta, Optima), Century Batteries, U.S. Battery).

- Look for Support/Resources Sections: Search for menu items like “Support,” “Resources,” “Technical Information,” “Downloads,” “Safety,” or “Product Information.”

- Find the SDS/Safety Data Sheet Link: Within these sections, look for a specific link labeled “Safety Data Sheets,” “SDS,” or sometimes “MSDS” (though SDS is the correct current term).

- Identify Your Battery Type: Manufacturers often list SDS documents categorized by battery chemistry (Lead-Acid, AGM, Lithium-Ion) or specific product lines. You might see listings like “SDS – Flooded Lead Acid,” “SDS – AGM Deep Cycle,” or “SDS – Lithium-Ion.” Select the one that matches your battery. Some sites might have a search function.

- Download the PDF: SDS documents are almost always provided as downloadable PDF files.

Contacting Suppliers or Retailers

If you purchased the battery through a distributor, wholesaler, or large retailer (especially for commercial purposes), they should be able to provide the SDS.

- Identify Your Supplier: Note where you purchased the battery.

- Contact Customer Service or Technical Support: Reach out to the supplier’s customer service or technical support department via phone or email.

- Request the SDS: Clearly state that you need the Safety Data Sheet for the specific battery model or type you purchased. Providing a part number can be helpful.

- Be Persistent: Suppliers fulfilling workplace orders are generally obligated to provide SDSs upon request. Retailers selling primarily to consumers might be less accustomed to these requests but should be able to obtain the document from their upstream supplier or the manufacturer.

Online Chemical Safety Databases

Several online databases aggregate SDS documents. While potentially useful, verifying the document’s accuracy and revision date against the manufacturer’s official source is crucial. These can be a secondary option if manufacturer/supplier routes fail.

Understanding SDS can seem technical, but this video provides a helpful visual overview of what Safety Data Sheets are and why they matter:

Tip: Always ensure you have the latest revision of the SDS, as formulations and regulatory information can change over time. The revision date is usually listed in Section 16 of the document.

FAQs About what does sds mean on a car battery

What does SDS stand for specifically regarding batteries?

SDS stands for Safety Data Sheet. Regarding batteries, it’s a document detailing the chemical hazards (like corrosive acid or flammable lithium), safe handling instructions, first aid measures, transport regulations, and disposal considerations specific to that battery type (e.g., lead-acid, AGM, lithium-ion).

Is an SDS the same as an MSDS for a battery?

No, not exactly. SDS (Safety Data Sheet) is the current, globally standardized format under the GHS (Globally Harmonized System) with a strict 16-section structure. MSDS (Material Safety Data Sheet) was the older, less standardized format. SDS has replaced MSDS, providing more consistent hazard information.

Why do lead-acid batteries need an SDS?

Lead-acid batteries require an SDS because they contain hazardous materials: corrosive sulfuric acid and toxic lead compounds. The SDS communicates these dangers, outlining risks like chemical burns, toxicity upon exposure, and proper handling procedures, fulfilling OSHA workplace safety and DOT transportation requirements.

Do lithium-ion car batteries require an SDS?

Yes, lithium-ion car batteries generally require an SDS. They contain flammable electrolytes and reactive lithium compounds, posing fire and chemical hazards. The SDS details these risks, safe handling protocols, fire-fighting measures (which differ from lead-acid), transport rules (Class 9), and disposal guidelines.

What hazard class are most car batteries?

For transportation purposes under DOT regulations:

* Wet, filled lead-acid batteries are typically Class 8 (Corrosive Material), UN2794.

* Lithium-ion batteries are typically Class 9 (Miscellaneous Hazardous Material), with various UN numbers like UN3480 or UN3481.

* Non-spillable batteries (AGM/Gel) might be Class 8 (UN2800) but can often ship under exceptions.

Where can I download a lead acid battery SDS PDF?

You can typically download a lead-acid battery SDS PDF from the battery manufacturer’s official website (look under “Support,” “Resources,” or “Safety Data Sheets”). Major brands like Interstate, East Penn (Deka), Clarios, or U.S. Battery provide these online. Alternatively, contact the supplier or retailer where you purchased it.

Do I need an SDS for a battery installed in my car?

Generally, no. As a consumer product installed and used under normal conditions in your vehicle, an SDS is not typically required or provided. However, an SDS is required for that same battery type in workplace settings (mechanic shops, retailers) and for transportation when shipped separately or in bulk.

What key safety information is in a battery SDS?

Key safety information includes: Hazard identification (corrosivity, toxicity, flammability), chemical composition, first-aid measures for exposure, fire-fighting guidance, safe handling/storage procedures, required Personal Protective Equipment (PPE), spill cleanup steps, transport classification (UN number, Hazard Class), and proper disposal/recycling information.

What does SLI mean on a car battery, and is it related to SDS?

SLI stands for Starting, Lighting, and Ignition. It describes the primary function of a standard car battery – providing a large burst of power to start the engine and powering lights/accessories. SLI is not directly related to SDS, which describes the safety and hazard information of the battery’s chemical components. An SLI battery will still have an associated SDS.

How is an AGM battery SDS different from a standard lead-acid SDS?

An AGM (Absorbent Glass Mat) battery is a type of lead-acid battery, but it’s typically “sealed” or “non-spillable.” While both SDSs will list lead and sulfuric acid hazards, the AGM SDS might reference different transport regulations (potentially UN2800 or non-spillable exceptions) compared to a standard “wet” lead-acid battery (UN2794). Handling precautions might also differ slightly due to the immobilized electrolyte in AGM batteries.

Summary

Navigating the world of car batteries involves understanding not just their performance but also their safety implications. The term SDS, or Safety Data Sheet, is a cornerstone of this understanding. It’s far more than just jargon; it’s a critical document mandated by safety regulations like OSHA’s HCS.

Key Takeaway: An SDS provides indispensable, standardized information about a car battery’s chemical hazards (like corrosivity or flammability), safe handling practices, emergency procedures, and regulatory compliance details, particularly vital for workplace safety and transportation.

Remember:

- SDS replaced the older MSDS format and follows the globally recognized 16-section GHS structure.

- It’s essential for workplaces handling batteries and for shipping batteries classified as hazardous materials.

- While distinct from Lithium Battery Test Summaries (UN 38.3) and EV Emergency Response Guides, the SDS provides the foundational chemical safety information.

- You can typically find a battery’s SDS on the manufacturer’s or supplier’s website.

By understanding what SDS means in the context of car batteries, you’re better equipped to handle these essential components safely and responsibly, ensuring compliance and protecting yourself and the environment.

Do you have any further questions about battery safety documents, or have you had experiences finding or using an SDS? Share your thoughts or questions in the comments below! Feel free to share this post if you found it helpful.